7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 1. Type and Hardness of Materials. The type and hardness of materials are the first factors to be considered in the selection of crushing equipment. Different types of materials will have different hardness and structure, which will have the primary limit on

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high

learn more

(PDF) Design of Impact stone crusher machine

2019年5月31日 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher.

learn more

Types of Stone Crushers Machine - Mineral

2024年1月3日 The types of stone hammers crushers: single-stage hammer crusher, high-efficiency hammer crusher, sand making machine, vertical shaft hammer rock crusher, reversible hammer crusher, double rotor

learn more

Crusher - an overview ScienceDirect Topics

They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact. A jaw crusher consists essentially

learn more

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日 Home. Econ. Human Resources. Performance Evaluation. Design and Performance Evaluation of a Stone Crusher. UNIOSUN Journal of Engineering and

learn more

A Comprehensive Guide to Stone Crusher

2023年2月22日 Some of the most common ones include jaw crushers, cone crushers, impact crushers, and hammer crushers. Each type of crusher machine has its unique features and benefits, depending on its use and

learn more

The influence of stone crushing processes on

2018年1月17日 Form, angularity and surface texture of five coarse and five fine aggregates, from three different quarries, were evaluated by means of digital image processing and were categorised by two different

learn more

The effect of rock crusher and rock type on the aggregate shape

Request PDF On Jan 10, 2020, Mojtaba Kamani and others published The effect of rock crusher and rock type on the aggregate shape Find, read and cite all the research you

learn more

pcbassam

2023年8月4日 Classification of Stone Crushing Units Based on the information received from SPCBs/PCCs, stone crushers may be ... The primary crusher breaks large stones an boulders into 100-140 mm size stones. Crushed stones are sent to seconda crusher for further reduction into smaller sizes. Various types of crushers are sedjn

learn more

The influence of stone crushing processes on

2018年1月17日 Form, angularity and surface texture of five coarse and five fine aggregates, from three different quarries, were evaluated by means of digital image processing and were categorised by two different

learn more

Rock Crushers, Stone Crushers, Screening and

Capacity (by hour) 165 - 790 mtph (182 - 871 stph) Feed opening. 1,200 x 830 mm (47 x 33 in.) mm. Motor power. 132 kW (200 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers,

learn more

Sand production with VSI crushing and air classification:

2015年7月1日 There are several types of static air classifiers available, namely Gravitational (G), Gravitational-Inertial (GI) and Centrifugal (C), and the type used will depend on the desired cut-size (Aslaksen Aasly et al., 2014).The most simple static air classifier is of the G type, see principle in Fig. 1.In a simplified way the process taking

learn more

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"":{"items":[{"name":"sbm 1 hammer mills with internal classifi ion.md","path":"sbm 1 hammer mills with internal ...

learn more

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

learn more

Coal crusher classification and working principle_Kefid

2023年6月9日 Extruded coal crusher mainly includes jaw crusher, cone crusher, roller crusher and so on. The working principle is: the material in the crusher fixed toothed plate and movable tooth plate squeezed, splitting and bending and was broken. Mainly used for hard material crushing, widely used in the field of metal mines and crushed stone.

learn more

Design of impact stone crusher machine - ResearchGate

2024年1月7日 Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores. ... 3.2 Classification of crusher . A crusher can be classified depending on the size ...

learn more

Aggregate Production Optimization in a Stone-Crushing

2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

learn more

How it Works: Crushers, Grinding Mills and

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can

learn more

Environmental Guidelines for Stone Crushing Units

2023年8月8日 The stone crushing process can be broadly divided in following stages: 3.1 Transportation of raw material: Stones extracted from various sources are transported to stone-crushing units by means of trucks, trailers or automatic dumpers. 3.2 Primary crushing: Mined stones are fed directly into the primary crusher through stone feeders.

learn more

classification of stone crusher - shibang-china

The worlds largest stone crusher manufacturers, specializing in the production of jaw crusher, stone crusher, counter-attack crusher, impact crusher, crusher machine ... AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized ...

learn more

Stone crusher, mobile crusher, grinding mill, ZGM Industrial

Industrial Grinder Mill. ZGM industrial milling equipment, energy-saving, high-yield, precision, environmental protection, adding orange vitality to the development of industry. ZGM Industry has 20 years of experience in the production and sales of crushers, grinding mills, sand making machines, sand washing machines and mobile crushers.

learn more

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

learn more

Primary and Secondary Crushing: Understanding the Basics

2023年2月28日 The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1. The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness, abrasiveness, and size of the materials. The cone crusher is the most common type of secondary crusher used in mining and quarrying operations.

learn more

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"":{"items":[{"name":"sbm 1 hammer mills with internal classifi ion.md","path":"sbm 1 hammer mills with internal ...

learn more

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

learn more

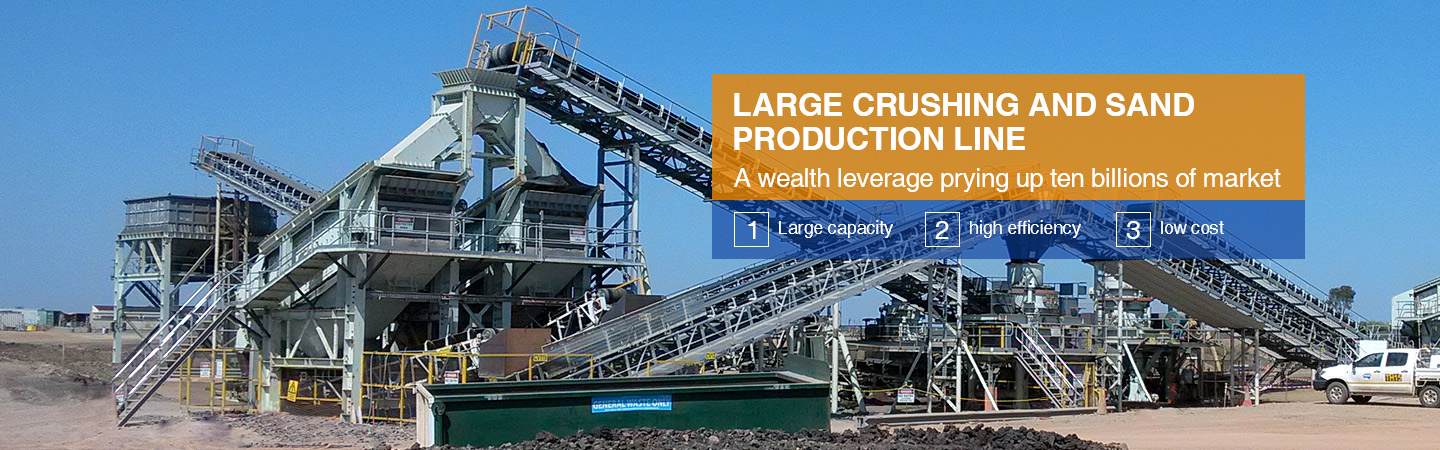

Stone Crusher Plant Design: Best Practices for Efficient

2023年2月28日 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production ...

learn more

« DESIGN OF A STONES CRUSHER MACHINE» - rufso

2022年4月11日 « DESIGN OF A STONES CRUSHER MACHINE» Review University without Border for the Open Society (RUFSO) ISSN: 2313-285X Volume: 32, Issue: 01, April 2022 ... 3.2 Classification of crusher A crusher can be classified depending on the size reduction factor as follows. a. Primary crusher: the raw material

learn more